Stainless steel sealing screws pan head socket cap A2

Stainless steel sealing screws are designed and manufactured with a cold formed groove beneath the head of the screws. overcome all these limitations by placing an O-ring under the head for sealing.

| Catalog | Special screws/ stainless steel sealing screws |

| Material | ss302, ss304,s s316, A2-70. A4-80 |

| Finish | Passivation or as custom request |

| Size | M1-M12mm |

| Head Drive | Pan head or as custom request |

| Drive | Philip, torx, six lobe, slot, pozidriv |

| MOQ | 10000pcs |

Stainless steel sealing screws

Why Pan head sealing screws Socket cap stainless steel A2 is a good choice ?

To overcome all these limitations by placing an O-ring under the head for sealing.

Assemble mating components using standard torque values.

Specify any common surface finish.

Metal-to-metal contact.

High re-usability.

Positive sealing from either side of the assembly.

Stainless steel sealing screws , as the screws are tightened, the O-ring is compressed, squeezing the O-ring between the groove and mating surface to complete the seal. The design of the groove controls the amount of compression to the O-ring. And because O-rings retain their elastic memory, Sealing screws are reusable time after time. The O-Ring groove is optional for 100° flathead fasteners. Standard 100° flatheads are without the O-Ring groove .

Stainless steel sealing screws, Pan head sealing screws Socket cap stainless steel A2 ,since it is stainless steel material , can be ss302, ss304, ss316, in good an-ti rust . Stainless Steel Fasteners are very good in corrosion resistant. They have an excellent life cycle, are environmentally friendly and are 100% Recyclable. They are also resistant to high heat as well as extremely cold temperatures making stainless steel fasteners the material of choice for almost any application!

Stainless steel is a low carbon steel that contains 10.5% or more chromium by weight. Chromium gives the steel its anti-corrosion property by allowing the formulation of an invisible chromium-oxide film on its surface which is known as a passive layer. This layer or film can self-repair if damaged mechanically or chemically when it has available oxygen, even in small quantities. The corrosion resistance of stainless steel may be enhanced by increasing the chromium content together with the addition of other elements to the alloy such as nickel, molybdenum and titanium.

Some similar products for your reference

sealing screw series 1

sealing screw series 2

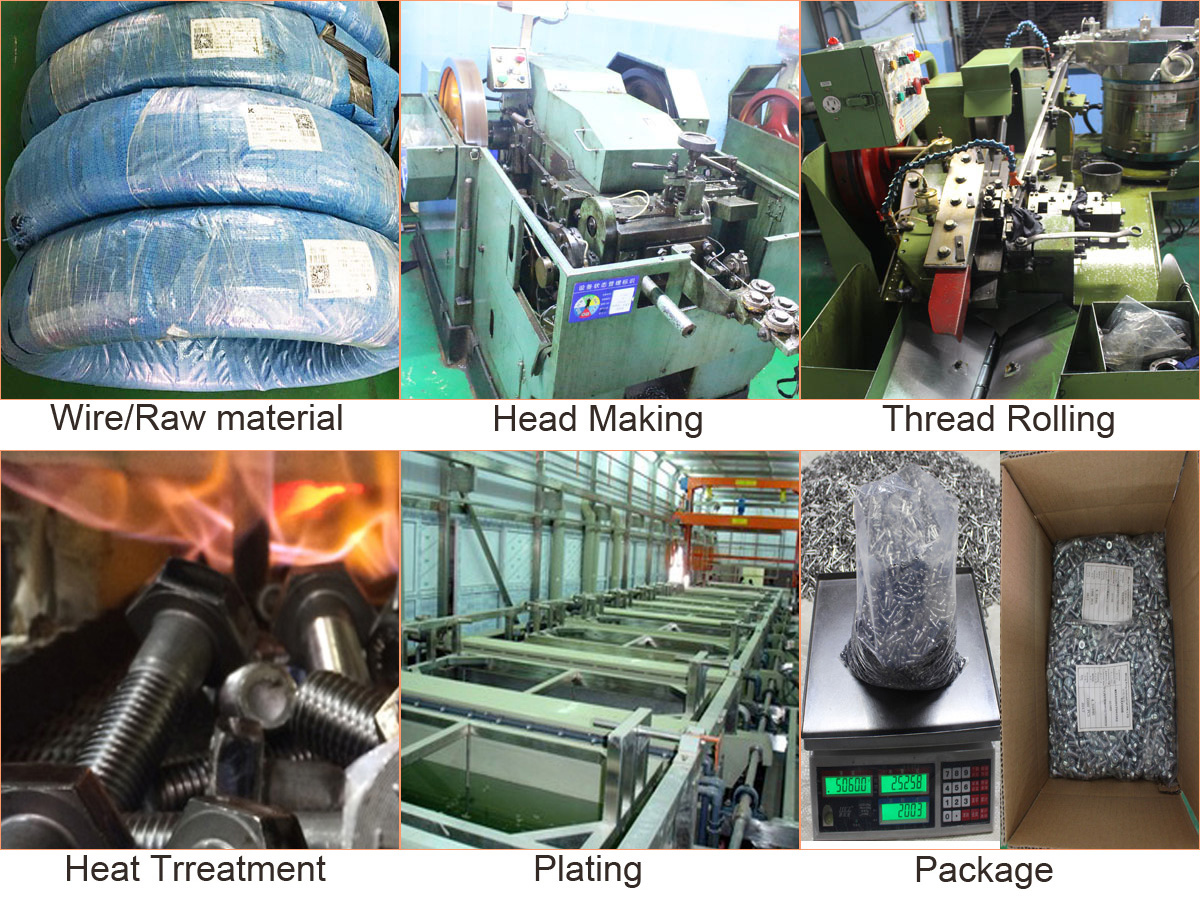

Screw manufacture Process

Mingxing Factory Overview

Mingxing Production LINE

Mingxing Certifications