Pozidriv is an improved version of the Phillips screw drive. They can be unscrewed with a regular Phillips screwdriver. It is jointly patented by the Phillips Screw Company and American Screw Company. The name is thought to be taken from the words “positive” and “drive”. Its advantage over Phillips drives is its decreased likelihood to cam out, which allows greater torque to be applied.In ANSI standards it is referred to as type IA.It is very similar to, and essentially compatible with, the Supadriv screw drive.

Phillips drivers have an intentional angle on the flanks and rounded corners so they will cam out of the slot before a power tool will twist off the screw head. The Pozidriv screws and drivers have straight sided flanks.

The Pozidriv screwdriver and screws are also visually distinguishable from Phillips by the second set of radial indentations set 45 degrees from the cross recess. The manufacturing process for Pozidriv screwdrivers is slightly more complex. The Phillips driver has four simple slots cut out of it, whereas in the Pozidriv each slot is the result of two machining processes at right angles. The result of this is that the arms of the cross are parallel-sided with the Pozidriv, and tapered with the Phillips.

This design is intended to decrease the likelihood that the Pozidriv screwdriver will slip out, provide a greater driving surface, and decrease wear. The chief disadvantage of Pozidriv screws is that they are visually quite similar to Phillips, thus many people are unaware of the difference or do not own the correct drivers for them, and use incorrect screwdrivers. This results in difficulty with removing the screw and damage to the recess, rendering any subsequent use of a correct screwdriver unsatisfactory. Phillips screwdrivers will fit in and turn Pozidriv screws, but will cam out if enough torque is applied, potentially damaging the screw head. The drive wings on a Pozidriv screwdriver will not fit a Phillips screw correctly, and are likely to slip or tear out the screw head.

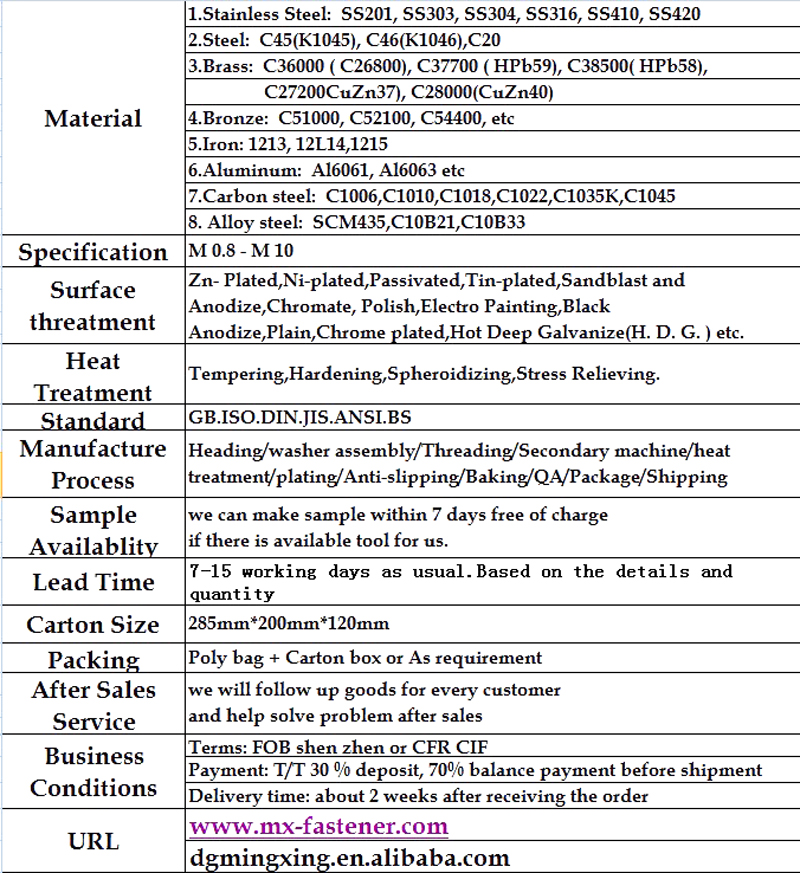

what we can do

Various kinds of fasteners for you reference

Cardboard package or as requested

1 :We can provide samples in 7 days

2 :Provide custom made service

3 :We can help you develop new product

4 :Quality assurance

5 :Factory price

M-sing Screw Factory with a mature production technology and sophisticated processing techniques, improved detection methods, with the development of strong design capabilities, product quality, the introduction of domestic and international high-precision molds and high-quality raw materials. The main production line with GB, Japan’s JIS, the United States ANSI, the German DIN, BS British standards of bolts, and customers can request all kinds of difficult design and production of standard parts. And through third-party authoritative testing agencies product testing, qualified in the relevant report. Re-header equipment, Roll Machine, tail-cutting, stamping machines, slot milling machines, line cutting, automatic lathes, and other production equipment, some of which more machinery assembling a computer-controlled, automatic detection display, can provide the steady and rapid Zero tolerance of the product, the monthly production capacity of several 10 million.

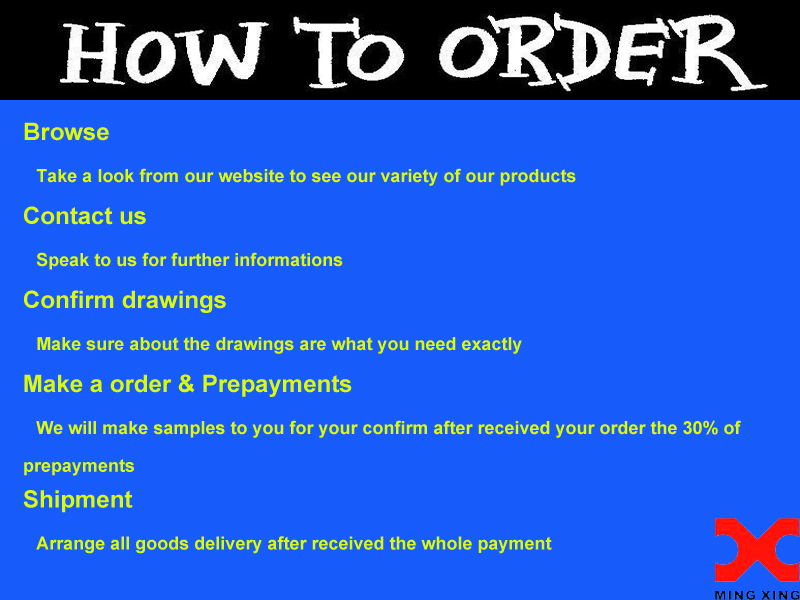

How to buy from us

1 : We accept all kinds of payment

2 : Provide a tiny order if the products needed in our warehouse

3 : We will reply your email as much as 15 hours